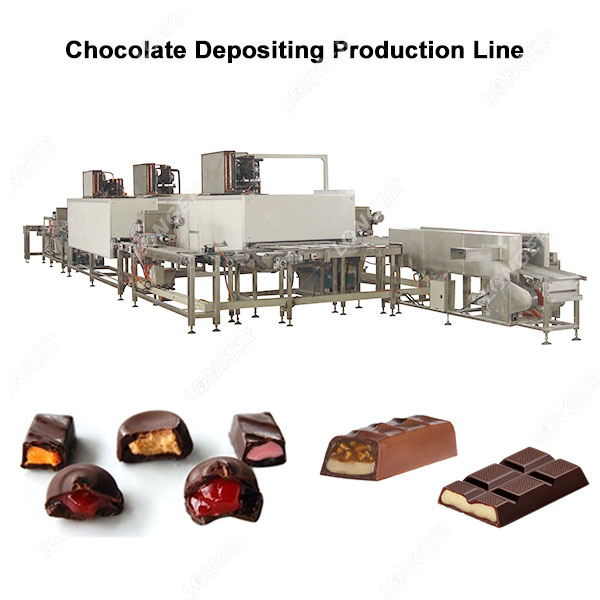

The chocolate depositing production line can complete the whole process from depositing, molding to discharging. This set of equipment can be used to manufacture a variety of different shapes of pure chocolate, chocolate bars, mixed chocolate with nuts, and chocolate with fillings. The chocolate has accurate quantification, smooth surface and high quality.

Structure of PLC Chocolate Depositing Machine

This machine is mainly composed of: main transmission parts, mold drying parts, depositing heads (three, the first of which is servo depositing, and the rest are pneumatic depositing), vibration mechanism, crushed nuts adding mechanism, template loop parts, cooling air duct It is composed of components, demoulding mechanism, heat preservation system, electrical control system, etc.

Main Working Principle of Chocolate Depositing Production Line

When producing chocolate, the depositing head injects the chocolate slurry into the mold cavity fixed on the chain, then sends it to the vibrating section for vibration, and then enters the cooling section for cooling; enters the secondary depositing station, and adds crushed fruit after depositing After the mold is baked, it enters the third depositing station, depositing, vibrating, and then cooling.

The cooled chocolate template enters the stripping section, and the stripped chocolate is sent out by the conveyor belt.

Features of PLC Control Chocolate Depositing Line

- It is widely used and can pour a variety of pure chocolate and sandwich chocolate in different shapes.

- Depositing, molding, demoulding, freezing and other processes are all carried out automatically, reducing labor.

- Mechanical transmission, accurate positioning, precise depositing and dosing.

- The PLC and touch screen adopt Siemens, which is easier to operate and requires less labor.

- The PLC and touch screen control the entire processing line, and the touch screen displays faults to facilitate problem solving;

- The cover body, mesh belt and parts in contact with materials or finished products are all made of 304 stainless steel.

- High-quality equipment with stable performance can realize 24-hour continuous production.

How To Adjust The Amount Of Chocolate Depositing?

- The servo depositing head adjusts the total amount of depositing at each depositing point by adjusting the length of the depositing stroke on the operation screen, so that the depositing amount reaches the required chocolate depositing amount.

- The pneumatic depositing head can adjust the total amount of depositing at each depositing point by adjusting the stroke of the depositing cylinder, so that the depositing amount can reach the required chocolate depositing amount.

Parameter of Best Chocolate Depositing Production Line

| Model | LG-CJZ175 | LG-CJZ175 (Two Head) | LG-CJZ510 | LG-CJZ510 (Two Head) |

| Capacity(mould pieces/min) | 6-15 | 6-15 | 6-15 | 6-15 |

| Power(KW) | 19 | 23 | 21 | 25 |

| Quantity of Moulds(pieces) | 280 | 330 | 280 | 330 |

| Size of Mould(mm) | 330*200*30 | 330*200*30 | 510*200*30 | 510*200*30 |

| Weight(KG) | 3500 | 4500 | 4000 | 5000 |

| Size of Machine(mm) | 16000*1000*1600 | 16000*1000*1800 | 16000*2000*1600 | 16000*2000*1800 |

Send us your request and we will provide you with a complete chocolate solution and quotation.

Email: serena@machinehall.com WhatsApp/Mobile: +8615515597212

Reviews

There are no reviews yet.