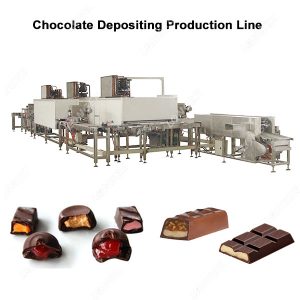

This chocolate moulding machine is a fully automatic and modern depositing line. It can complete the production process of chocolate: mould drying, pouring, vibration mould, cooling, demoulding and conveying. This chocolate moulding line can be widely used to produce single-color, left-right double-color, top-bottom double-color and paste-filled chocolate.

Features & Advantages of Chocolate Moulding Line

- Fully automatic PLC control, simple and convenient operation.

- Remote monitoring and remote debugging. Through the network connection, remote troubleshooting and diagnosis can be carried out on the Internet.

- The remote program can be modified according to the needs of users, which is simple and quick.

- The molding pouring machine uses the frequency conversion (servo) motor stroke to control the pouring volume. The pouring quantitative control is accurate, the error does not exceed 2G, and there is no template without pouring.

- It is made of SUS304 stainless steel and meets food production safety standards.

- Customized molds. You can produce chocolates of different sizes and chocolates with different patterns.

- Produce different kinds of chocolate products. You only need to replace the pouring head or the chocolate sauce distribution plate.

Chocolate Mold

The mold plate material is polycarbonate, which has good plasticity, good strength and roughness, and its specific heat capacity and thermal conductivity are similar to those of chocolate, and it has better demolding performance.

Template size: 330*200*30mm, 280 templates

Application of Automatic Chocolate Moulding Machine

You can choose a single-head, double-head or three-head chocolate depositing machine to produce different chocolates, such as solid color chocolate, left and right double chocolates, upper and lower double color chocolates, chocolate nuts, heart-filled chocolates, etc.

You can also choose to add a melting pot, a refiner, a tempering machine, etc. to form a complete chocolate production line. You can also add a spreader, a decorator, a biscuit feeder, etc. to produce more chocolate production.

Parameter of Chocolate Molding Machine

| Model | LG-CJZ150 | LG-CJZ175 | LG-CJZ175 (Two Shot) | LG-CJZ510 | LG-CJZ510 (Two Shot) |

| Capacity(mould pieces/min) | 6-15 | 6-15 | 6-15 | 6-15 | 6-15 |

| Power(KW) | 6 | 19 | 23 | 21 | 25 |

| Quantity of Moulds(pieces) | 200 | 280 | 330 | 280 | 330 |

| Size of Mould(mm) | 275*175*30 | 330*200*30 | 330*200*30 | 510*200*30 | 510*200*30 |

| Weight(KG) | 500 | 3500 | 4500 | 4000 | 5000 |

| Size of Machine(mm) | 4000*520*1500 | 16000*1000*1600 | 16000*1000*1800 | 16000*2000*1600 | 16000*2000*1800 |

Chocolate Moulding Process:

- The temperature-regulated chocolate material is sent to the hopper of the molding machine, and the jacket heating device keeps the material temperature. Then inject the material accurately and quantitatively into the lower mold plate;

- The die plate enters the vibration zone. Remove the air bubbles in the material on the vibrator, and make the material evenly distributed in the mold plate;

- The mold plate enters the cooling tunnel with multi-level operation. A refrigeration unit and a blower are installed above the tunnel, and cold air circulates in the tunnel to reduce the temperature of the material. The cold air temperature can be adjusted to maintain different cooling temperatures in each section;

- After the chocolate solidifies and shrinks, the mold plate enters the demolding area. Before demolding, it undergoes another vibration, the mold plate is turned over, and the chocolate and the mold are separated. Then, the conveyor belt transports the chocolate to the packaging system.

Sherry –

The chocolate produced by this machine is perfect, thank you very much.