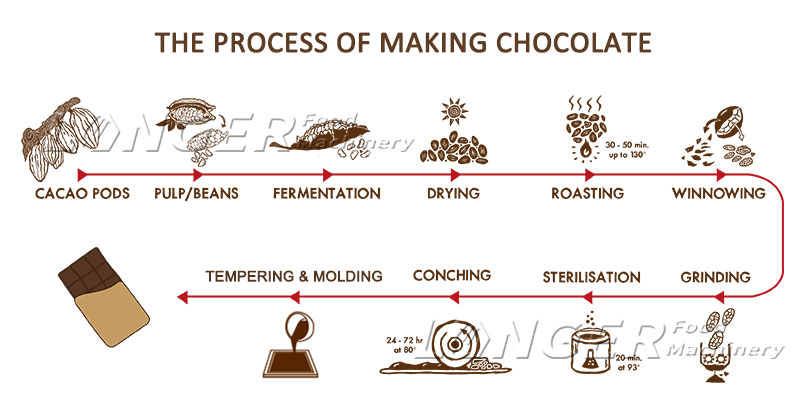

Chocolate is one of the most popular food items all over the world. The rich and creamy taste of chocolate makes it a favorite among people of all ages. But have you ever wondered what is the process of making chocolate? It can roughly be divided into 6 steps, the following is a step-by-step guide.

Step 1: Harvesting and Fermenting the Cacao Beans

The first step in making chocolate is harvesting the cacao beans. Cacao trees grow in tropical regions, and the beans are harvested twice a year. After harvesting, the beans are removed from their pods and fermented for a few days. This fermentation process helps to develop the flavor of the cocoa beans.

Step 2: Drying and Roasting the Beans

After fermentation, the beans are dried in the sun. Once they are completely dry, they are roasted in a roasting machine. Roasting helps to bring out the aroma and flavor of the beans.The roasting process is critical as it determines the final taste and color of the chocolate.

Step 3: Crushing and Grinding the Beans

After roasting, the cocoa beans are crushed into small pieces called nibs, which are then ground into a paste called cocoa liquor. This paste is made up of cocoa solids and cocoa butter.Cocoa liquor is the main ingredient used in the production of chocolate.

Step 4: Separating Cocoa Solids and Cocoa Butter

The cocoa liquor is then pressed to separate the cocoa solids from the cocoa butter. The cocoa solids are used to make cocoa powder, while the cocoa butter is used to make chocolate.

Step 5: Mixing and Conching

The cocoa solids and cocoa butter are then mixed together and ground into a smooth paste. This process is called conching. Cocoa liquor can also be mixed directly with sugar and other ingredients such as milk powder and vanilla before refining. A professional chocolate conche is essential, conching helps develop the flavor and smoothness of the chocolate.

Step 6: Tempering and Molding

The final step in making chocolate is tempering and molding. The chocolate is heated and cooled to a specific temperature to give it a shiny appearance and a smooth texture. Chocolate factories usually use chocolate tempering machines, which can achieve precise tempering.

Once tempered, the chocolate is poured into molds and allowed to cool and harden. The chocolate can be molded into different shapes and sizes, such as bars, truffles, and bonbons. The chocolate molding machine can realize mass production, and the mold can be customized.

And there you have it – the process of making chocolate! From harvesting the cacao beans to molding the finished product, each step is carefully carried out to create the delicious chocolate that we all love.